Plate and Frame Heat Exchanger Cleaning

Cleaning heat exchanger plates and refurbishing the frame improves efficiency and saves money. Equipment operating for extended periods requires regular maintenance and repair. During operation, heat exchangers accumulate fouling, scale, rust, and gasket issues, leading to reduced efficiency. If left unaddressed, this can eventually cause complete failure and emergency situations. Our services offer customers the same satisfaction and guarantee as OEMs, but at a lower cost and shorter turnaround time.

Our 7 Step Plate Cleaning and Refurbishment Process

Step 1:

Initial Plate Pack Review checking for any noticeable damage that can cause plate failure.

During this time all gaskets will be removed, and the gasket track checked for any deformities that will prevent proper gasket install.

Step 2:

Pressure washing of each plate to remove any and all loose debris before entering the chemical bath station.

Step 3:

Plates will enter a chemical bath to ensure fouling, scale, and rust build up on the plates are cleaned off.

Step 4:

Pressure wash Plates to insure any and all chemical residue is cleaned off. All plates will then be dried before entering the Dye Test station.

Step 5:

All plates will go through our Dye Penetrant test to ensure all 100% are in good working condition. This step is critical to ensure all plates are not showing signs of pinholes or cracks that would allow for cross contamination.

Step 6:

Final pressure wash to ensure all plates are chemical and dye penetrant free.

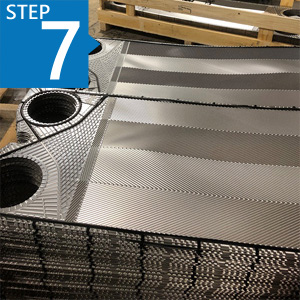

Step 7:

Installation of new gaskets and final plate arrangement for easy customer install.

On-Site Service

Our team of highly trained professionals are ready at all times to come on-site and service your Gasketed Plate and Frame Heat Exchangers. We understand that in some cases there is not enough time to have a unit or plate pack sent out to be serviced due to short shut down periods or an emergency.

We will arrive on site and conduct an initial inspection of the heat exchangers. Our crew will then open the unit and pressure wash both sides of each plate in the unit. Once the pressure washing is completed, we will then inspect each plate looking for any damage to the plates. After the inspection is complete, we will then provide and install new gaskets and place them on the plates then close the unit.

Note: We have the capabilities to receive and refurbish entire units. Each unit will undergo a final pressure test to guarantee no leakage before being sent back to the customer.

Frame Refurbishment Services

Benns Industrial Solutions Inc. also offers a Frame Handling package. After we receive your entire unit, we will do an initial inspection of the frame and tie rods. If needed, we will then sand blast the unit and apply a new paint coat with the color of your choice.

Once the plate pack has gone through our 7 step refurbishment process, we will then install the plate pack back into the unit and conduct a final Hydro test.